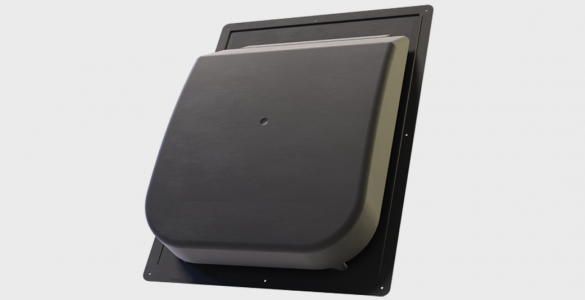

Home » Products » Ventilation » Steep-Slope » Python™ 65 Slant Back Vent

Python™ 65 Slant Back Vent

The patented Python 65 Slant Back Vent can be used as an intake or exhaust vent. Its innovative design features a lower profile than most static vents on the market, making it less visible on the roof for greater curb appeal. Its durable no-break polypropylene construction also eliminates unsightly dents and rust.